Catalog of production » Sewage pumping stations KNS

Sewage pumping stations KNS

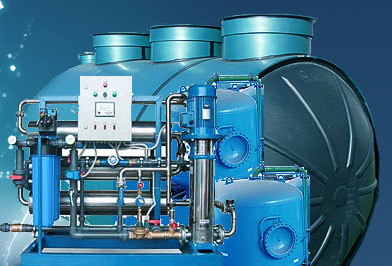

"Environmental Aquatic Center construction technology " develops and produces a sewage pumping station ( SPS ) of glass , plastic and metal. Sewage pumping stations are made of various diameters ranging from 800 mm to 5000 mm and a capacity of up to 10,000 m3/hr .

Sewage pumping station is designed for pumping waste water and is a ruggedized chassis in the form of a vertical cylinder of reinforced fiberglass, plastic or steel. Inside (CND ) are mounted in steel pipes , valves, check valves and pumping equipment. Number of pumps is determined individually , usually from 1 to 3 pieces.

The pumps sets the control cabinet, which is set in the immediate vicinity of the sewage pumping station, or in the auxiliary building. Information on the level of water in the control cabinet give the float switches that are installed at different levels within the body .

For ease of maintenance within the larger constellation arrange a fixed ladder with a platform at the level of the check valves and valves. To keep the body in the hills of staff to a minimum , the pumps are installed in a special plug connector, which is part of the pedestal, rigidly fixed to the bottom of the housing. The compound has a rubber seal with an apron . The pump is lowered into the building for a long chain or electric hoists for precise alignment with the compound in the body is installed guide rail to its full height.

Pumps can be dry or immersion type required characteristics are selected based on their specific requirements in terms of elevation, path length , diameter and material of the route, and also for reasons of cost and energy saving.

The composition of the sewage pumping station.

1. pumps

2 . The inner pipe

3 . float switches

4 . check valve

5 . catch

6. maintenance hatch

7. panel

8. ventilation

9. Inlet manifold

10 . anchor bolts

11. pressure manifold

12. ladder

13. maintenance area

14. Soroulavlivayuschaya basket

Most often, sewage pumping stations CND issued without additional structures ( aboveground building over them.) As a variant of the sewage plants may be built of metal prefabricated pavilions of light structures , such as corrugated steel sheeting , lumber. Such facilities are required to contain the air , hoisting devices , as well as the control room . Such structures facilitate the repair and maintenance of sewage pumping stations.

Durability and reliability of the sewage pumping stations provide capacity of polystyrene reinforced with fiberglass. Such structures withstand high load of the soil and groundwater. Corrosion protection is the use of stainless steel, epoxy and polyester fiberglass . These materials make it possible to extend the life of the ANC for more than 40 years. In addition, costs are reduced by anti-corrosion treatment case.

Polyester resin reinforced with glass fibers used in the manufacture of the same body and ends CND . Cover and grill in the neck of the station provides a level of safety in the operation of the pumping station near the crowded places . Waste water fed into the inside of the container through the sleeve through the wall of the deduced station.

In order to increase the life of the sewage pumping station , opposite gravity collector set soroulavlivayuschaya special basket made of stainless steel. This basket catches large solid particles , thereby filtering runoff and protecting the ANC itself .

One of the important elements of the sewage pumping stations is a submersible pump unit or dry installation. As these units are used pumps leading Western manufacturers such as Grundfos ( Denmark ), Flygt ( Sweden) , and other well-known brands. Standard features CND involves the installation of one to ten of these pumps that attach to the discharge port without bolting . Uses its own weight of the pump unit and moving the gripper can move vertically along the guide rails . This solution facilitates the work of installation / removal and maintenance of pumping units themselves . Reliability design of the plant is provided with metal plates at the base of the multi-layer fiberglass, which carries the pump nozzles.

Internally the pipes are made of stainless steel. Penstock KNS goes from each valve and has a wedge mechanical valve and ball check valve.

In order to eliminate the possibility of accumulation of gases in the tank , sewage pumping station has a ventilation system . The output of gases through the ventilation pipe CND outcropping . In addition, access to units of sewage pumping station installed inside the station stairs .

By the plate pump station is mounted to the plate with anchor bolts . For the convenience of the CND is equipped with lifting eyes and cable glands . Manhole cover goes with warming .

The pumps operate automatically and are controlled by signals from the float switches . All of them , and floats and pumps are connected to the control cabinet. Sami float switch on / off pumps are hung inside the ANC in a special holder. These sensors include: total float off , the float and the float pump start an alarm.